When we want to repair a hard disk damaged because of the PCB failure, we can usually find and replace a matching PCB, how to match the Toshiba PCB you can refer to our article: How to replace the Toshiba HDD PCB. Replacement Toshiba PCB G002901A can be ordered on HDDZone.com.

For most HDDs, although you find the right matching PCB, a simple replacement will not make the drive work, you also need to take the more important step of transferring the PCB’s firmware (also known as BIOS swapping).

Why do you need to transfer the PCB firmware?

- Information matching: The firmware of the hard disk contains the specific parameters, configuration information, and adaptation information of the hard disk. This information is essential for the drive to function properly and is critical to the correct identification and operation of the drive. The firmware of each drive is unique and closely related to the hardware characteristics of that drive. If the board is replaced without transferring the firmware, the new board will not be able to obtain these specific information from the original hard drive, and will not be able to interact properly with the platter, resulting in the drive not working properly. If the hard disk does not respond when powered on, the hard disk cannot be correctly identified, and the data read and write are abnormal.

- Encryption and authentication: Some hard drive manufacturers will encrypt the firmware of the hard drive or set up a specific authentication mechanism. Only when the original firmware matches the hardware of the hard drive can it pass the certification and make the hard disk operate normally.

- Maintain Data Integrity: Boot information storage: The firmware contains the bootloader and initialization information of the hard disk. This information is read first when the drive is booted, used to boot the drive into normal working order, and to prepare it for subsequent data reads and storage. Without the correct firmware, the drive may not boot properly and therefore cannot access the data stored on the platter, and transferring the firmware can ensure that this critical boot information is retained and used correctly.

- Data storage management: The firmware is also responsible for the management of data storage on the hard disk, including sector allocation, data read and write control, error verification and other functions. If the firmware is missing or mismatched, it can lead to read and write errors, loss, or corruption of the data.

- Bug Fixes and Compatibility:Original Troubleshooting: In some cases, the failure of the hard drive may not only be a problem with the board, but also related to the firmware. For example, there may be a corrupted, buggy, or incompatible version of the firmware, which causes the drive to not work properly. Transferring the firmware while repairing the circuit board can check and repair the firmware, so as to solve possible firmware problems and improve the success rate of hard disk repair.

- New Board Compatibility: Even if the replacement board is the same model as the original hard drive, there may be subtle differences in hardware design between different batches or different production times. By transferring the firmware, you can make the firmware of the hard disk better compatible with the new circuit board, and avoid compatibility problems caused by hardware differences.

Is it complicated to transfer PCB firmware?

Transferring hard disk PCB firmware is complex, and transferring firmware usually requires the use of professional tools and equipment, such as programmers, soldering station, etc.

1. Use a programmer to read and write firmware

Programmers (such as CH341A Programmer) are used to read and write firmware information, different models of hard disks may require different types of programmers, and the programming parameters need to be set correctly to ensure that the firmware is read and written correctly. The programmer can meet the basic chip programming needs, but for some complex chips or advanced functions, the support may not be perfect.

2. Use a soldering station to remove and solder the BIOS chip

Most of the hard disk firmware is stored in the BIOS chip(s) of the PCB, we only need to replace the BIOS chip, the BIOS chip has 8 pins, it is easier to replace the BIOS chip.

There are also some PCBs’ firmware stored in the “Main Controller Chip”, the “Main Controller Chip” has a lot of feet, removal and soldering is more complicated, requires a certain amount of technology, so we do not recommend trying it yourself.

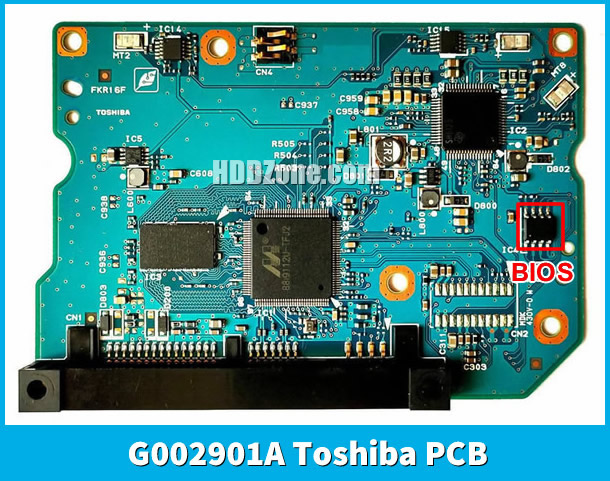

For Toshiba PCB G002901A, his BIOS chip is shown in the figure below:

Steps to remove and solder BIOS chip using a soldering station:

- Remove the BIOS chip from the original PCB;

- Remove the BIOS chip from the replacement PCB;

- Solder the BIOS chip of the original PCB to the replacement PCB;

Precautions for using a soldering station to remove and solder BIOS chips:

- Please adjust the temperature and wind speed of the heat gun according to the requirements of the circuit board and chip. In general, the temperature is between 300-350°C and the wind speed is around 3-4 gears.

- Please make sure that the text direction of the chip is consistent and do not make a mistake.

- For other tools you may also need tweezers, solder, flux, etc.

- you can find nearby electronic repair, mobile phone repair, computer repair personnel to help, the charge is 5-20 US dollars.

- It is advisable to understand the relevant knowledge and skills and practice well before proceeding.

Summary: It can be seen that when repairing a Toshiba PCB G002901A, it is relatively simple to find a replacement board, and it is more important to transfer the firmware. If you can handle it correctly, then congratulations, your hard drive is back to normal. If you have any questions, please feel free to contact us.

HDDZone.com provides all kinds of hard drive PCB boards. Free shipping worldwide!

HDD PCB Online Shop: HDDZone.com

Useful Guide: Hard Drive PCB Replacement

Contact US: Please feel free to contact us by email sales@hddzone.com.

Note: Send clear photos of your PCB (both sides) by attachments will make everything easier!